Is ‘Just-in-Time’ a relic of a time gone by in Australia? - JLL

Contact

Is ‘Just-in-Time’ a relic of a time gone by in Australia? - JLL

While some space relief for occupiers is coming via improved supply chain efficiency, ‘just-in-time’ inventory management is still a long way off returning, says Xavier Wilson - JLL Research Analyst – Australia.

Since the beginning of the COVID-19 pandemic, international and domestic supply chains alike have suffered drastically, prompting a move away from the highly lean ‘just-in-time’ inventory management model towards the ‘just-in-case’ approach. Throughout the 2010s, the common goal of most supply chain managers was to get as lean and as efficient as possible and finding a cost-effective manufacturer to help accomplish this. However, this meant supply chains were vulnerable to single points of failure, which the pandemic and its’ myriad of trade disruptions quickly provided in abundance. Since the onset of COVID-19, a far greater level of manufacturing diversification has been achieved. Supply chains now actively seek to spread manufacturers across geographies while reducing any single points of failure derived from transportation and distribution (Butt, 2022).

Unsurprisingly, international supply chains have been most affected. According to JLL’s Supply Chain team, the majority of Australian occupiers now need to hold approximately 30% more inventory relative to pre-pandemic levels with the Fast-Moving Consumer Goods (FMCG) players now having the highest requirements. Domestic supply chains - thanks to their natural agility and the trend towards onshoring of manufacturing – are less reliant on the ‘just-in-case’ approach, however, have nonetheless adopted higher than pre-COVID inventory levels. As supply chain pressures and pain points ease, we expect inventory levels to come in by 5%-10% over the medium-term (JLL Supply Chain), however, a complete return to ‘just-in-time’ is still a long way off.

Impact on occupier demand

The aforementioned supply chain difficulties originally resulted in a substantial uptick in gross take-up levels, mainly from 3PLs and retailers. Both the Retail Trade & Transport, Postal & Warehousing sectors exceeded the previous record national annual gross take-up for their sectors during the pandemic by 59.4% (2020) and 34.2% (2021), respectively (Source: JLL Research).

However, in a historically tight vacancy environment in the Australian industrial market, the true level of demand is not accurately represented in gross take-up levels. Many occupiers are forced into incubation, taking smaller than desired spaces on short-term leases whilst looking to secure a pre-lease for a larger space in the future. Conversely, some occupiers found themselves with too much space on their hands after initially overestimating future requirements and are now sub-leasing any excess space.

All things equal, easing supply chain bottlenecks will aid the availability issues across the industrial market and reduce stress on overflow storage facilities. Ultimately, while the worst is likely behind us, lean supply chains are simply not possible any time soon. Problems in ports and persistently prevalent bottlenecks in China remain unresolved.

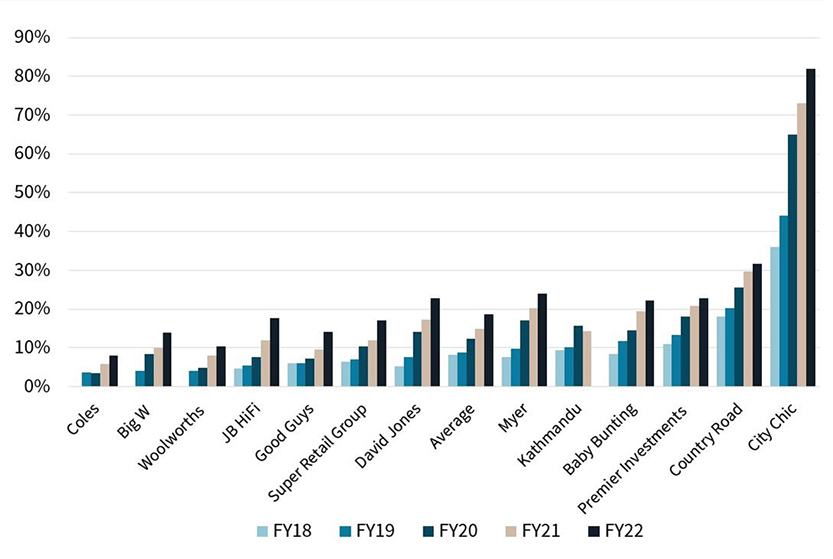

Despite this, occupier activity is expected to normalise to pre-COVID levels, with a more fluid sub-lease market likely to mitigate some occupier space relinquishment. The tailwinds exhibited throughout the pandemic, namely eCommerce adoption, are likely to be structural, with many groups deriving a larger share of their revenue from online sales, supporting the holistic strength of the industrial sector over the medium-to-long term.

By Xavier Wilson - JLL Research Analyst – Australia

This article was published on 7 March 2023 on www.jll.com.au

Related Reading:

Port access drives Melbourne logistics

How a supply chain rethink is bolstering industrial real estate - JLL

Second strongest yearly result of gross take up of logistics and industrial space in 2022 - JLL

Why real estate is confused about sustainability - JLL Podcast

Figure 1: Retailer revenue derived from online sales in Australia